Markem Imaje

Worldwide leader for product identification and traceability solutions.

Markem-Imaje is a trusted world manufacturer of product identification and traceability solutions, offering a full line of reliable and innovative inkjet, thermal transfer, laser, print and apply label systems and RFID-based systems. Markem-Imaje delivers fully integrated solutions that enable product quality and safety, regulatory and retailer compliance, better product recalls and improved manufacturing processes. Markem-Imaje can rely on 30 subsidiaries worldwide to provide more than 40,000 customer with optimal product marking and coding solutions.

Markem-Imaje is a trusted world manufacturer of product identification and traceability solutions, offering a full line of reliable and innovative inkjet, thermal transfer, laser, print and apply label systems and RFID-based systems. Markem-Imaje delivers fully integrated solutions that enable product quality and safety, regulatory and retailer compliance, better product recalls and improved manufacturing processes. Markem-Imaje can rely on 30 subsidiaries worldwide to provide more than 40,000 customer with optimal product marking and coding solutions.

Product Line

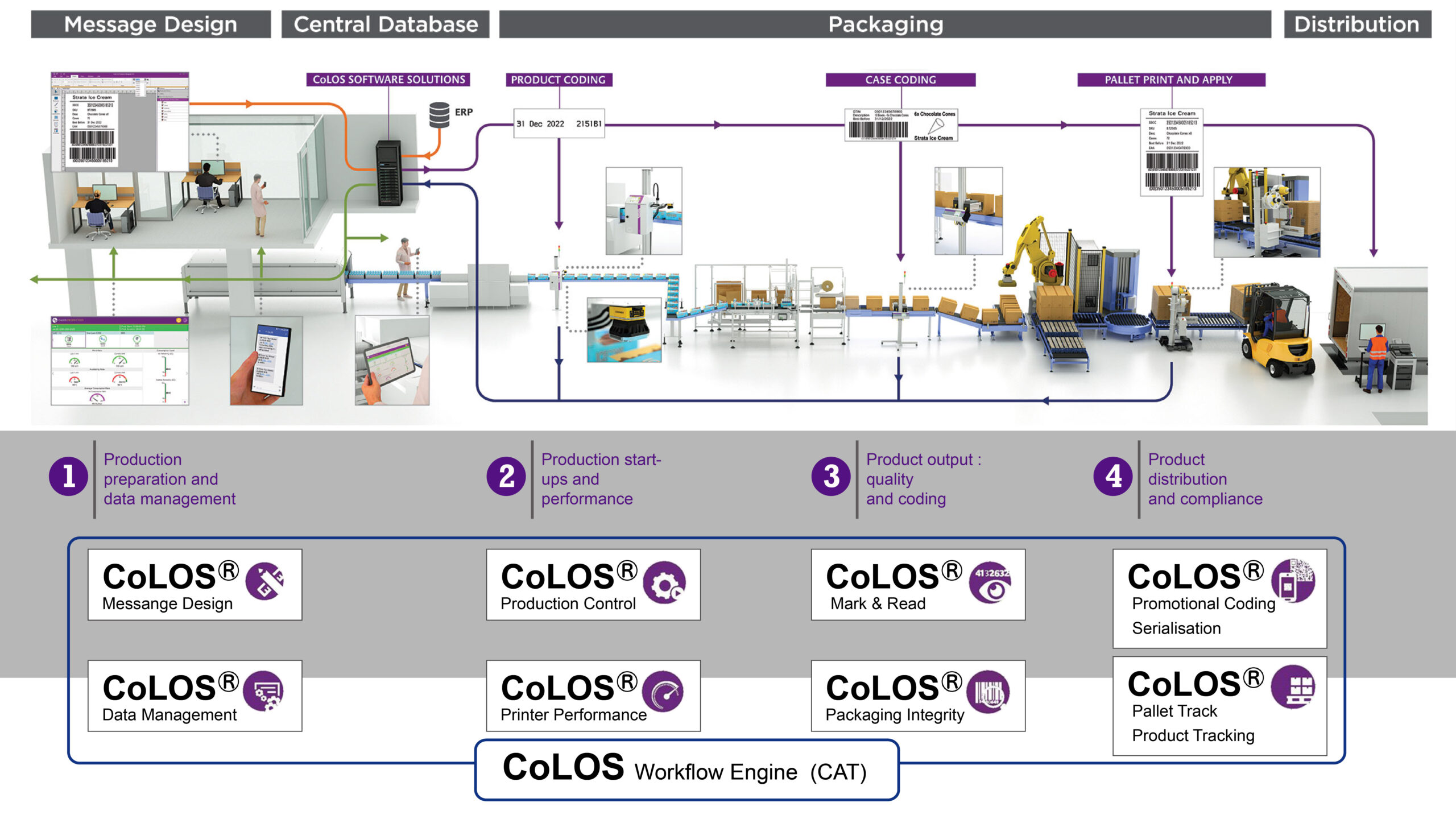

Industrial Coding and Traceability Software

We understand the product identification and traceability challenges you face throughout the lifecycle of your products. Today’s industrial coding and packaging must comply with changing regulations, keep products safe, and be traceable throughout the supply chain.

Systech, a solutions division of Markem-Imaje, delivers automated coding optimization software and end-to-end supply chain tracking to meet these demanding requirements—all while increasing productivity and minimizing human error and costs.

Our package coding and label management automation helps you accurately handle complex messages and streamline production. Reduce the costs of manual entry and message data maintenance by up to 90% and cut changeover duration by up to 50%.

Automated message design, fewer mistakes

- Design and manage complex messages from one central, intuitive interface Accelerate line startup and changeover time, SKU data entry, and message data maintenance

- Accelerate line startup and changeover time, SKU data entry, and message data maintenance

- Minimize risk of operator error and time spent manually copying data across production lines

Systech’s automated inspection solutions combine robust machine vision with intuitive interfaces to provide a one-stop-shop for integrated printing and verification. Our seamless platform confirms that your packaging and industrial coding are consistently compliant and of the highest quality.

Advanced vision inspection, dependable verification

- Verify package labeling, contents, and data for a broad variety of container types

- Scan and check 100% of codes and prints to detect and correct errors in real-time

- Minimize waste and prevent lost hours of production printing incorrect codes

Effective line control improves quality, reduces costs, and helps you continually increase production output. Systech automates coding and printing processes to minimize errors and optimize effectiveness from start-up through every phase of production.

Greater uptime, maximum OEE

- Select one correct job each time to avoid costly changeovers and minimize operator mistakes

- Instantly access performance indicators from printing and line equipment; get immediate alerts when problems occur

- Leverage real-time and historical data to identify bottlenecks, optimize printer performance and implement process improvements

As the industry leader and pioneer in serialization software, Systech delivers full-stack capabilities that can be deployed rapidly on any line, site, or enterprise in any region. Our serialization and track-and-trace software is configurable for unbeatable ease of implementation and speed to accommodate changing demands and meet regulatory compliance.

Proven, full-stack platform

- Create unique product identifiers, automate pallet labeling, and aggregate every packaging level for seamless traceability

- Provide site-level master data, serial number management, event reporting, and offline serialization packing operations

- Establish enterprise-level connectivity with comprehensive track-and-trace and compliance integrations

Mixing and matching traceability tools from different vendors can be overwhelming and costly. Systech provides a single, simple solution for generating, managing, and reporting product data in a diverse supply chain ecosystem. Our track-and-trace solution makes it easy to create a compliant system of record for your products in changing regulatory environments.

Secure, end-to-end supply chain tracking

- Get item transfer visibility and secure data exchange across your global supply chain

- Create, modify and order the processing of data based on your requirements

- Establish multiple levels of user restrictions and redundancy for everyone in your supply chain ecosystem

Product authentication at the individual item level is the most effective way to prevent counterfeiting and diversion. Systech’s revolutionary e-Fingerprint® technology turns your existing package barcode into a unique digital identifier. Each product becomes instantly connected to verify authenticity, gather actionable supply chain insight, and engage consumers.

Non-additive, digital connectivity

- Connect physical products to the digital supply chain for item-level authentication and traceability

- Detect product counterfeiting and diversion issues in real-time

- Deliver item-specific details and capture consumer feedback using a simple smartphone app

Product Line

Industrial Coding and Traceability Software

We understand the product identification and traceability challenges you face throughout the lifecycle of your products. Today’s industrial coding and packaging must comply with changing regulations, keep products safe, and be traceable throughout the supply chain.

Systech, a solutions division of Markem-Imaje, delivers automated coding optimization software and end-to-end supply chain tracking to meet these demanding requirements—all while increasing productivity and minimizing human error and costs.

Our package coding and label management automation helps you accurately handle complex messages and streamline production. Reduce the costs of manual entry and message data maintenance by up to 90% and cut changeover duration by up to 50%.

Automated message design, fewer mistakes

- Design and manage complex messages from one central, intuitive interface Accelerate line startup and changeover time, SKU data entry, and message data maintenance

- Accelerate line startup and changeover time, SKU data entry, and message data maintenance

- Minimize risk of operator error and time spent manually copying data across production lines

Systech’s automated inspection solutions combine robust machine vision with intuitive interfaces to provide a one-stop-shop for integrated printing and verification. Our seamless platform confirms that your packaging and industrial coding are consistently compliant and of the highest quality.

Advanced vision inspection, dependable verification

- Verify package labeling, contents, and data for a broad variety of container types

- Scan and check 100% of codes and prints to detect and correct errors in real-time

- Minimize waste and prevent lost hours of production printing incorrect codes

Effective line control improves quality, reduces costs, and helps you continually increase production output. Systech automates coding and printing processes to minimize errors and optimize effectiveness from start-up through every phase of production.

Greater uptime, maximum OEE

- Select one correct job each time to avoid costly changeovers and minimize operator mistakes

- Instantly access performance indicators from printing and line equipment; get immediate alerts when problems occur

- Leverage real-time and historical data to identify bottlenecks, optimize printer performance and implement process improvements

As the industry leader and pioneer in serialization software, Systech delivers full-stack capabilities that can be deployed rapidly on any line, site, or enterprise in any region. Our serialization and track-and-trace software is configurable for unbeatable ease of implementation and speed to accommodate changing demands and meet regulatory compliance.

Proven, full-stack platform

- Create unique product identifiers, automate pallet labeling, and aggregate every packaging level for seamless traceability

- Provide site-level master data, serial number management, event reporting, and offline serialization packing operations

- Establish enterprise-level connectivity with comprehensive track-and-trace and compliance integrations

Mixing and matching traceability tools from different vendors can be overwhelming and costly. Systech provides a single, simple solution for generating, managing, and reporting product data in a diverse supply chain ecosystem. Our track-and-trace solution makes it easy to create a compliant system of record for your products in changing regulatory environments.

Secure, end-to-end supply chain tracking

- Get item transfer visibility and secure data exchange across your global supply chain

- Create, modify and order the processing of data based on your requirements

- Establish multiple levels of user restrictions and redundancy for everyone in your supply chain ecosystem

Product authentication at the individual item level is the most effective way to prevent counterfeiting and diversion. Systech’s revolutionary e-Fingerprint® technology turns your existing package barcode into a unique digital identifier. Each product becomes instantly connected to verify authenticity, gather actionable supply chain insight, and engage consumers.

Non-additive, digital connectivity

- Connect physical products to the digital supply chain for item-level authentication and traceability

- Detect product counterfeiting and diversion issues in real-time

- Deliver item-specific details and capture consumer feedback using a simple smartphone app

Product Line

Industrial Coding and Traceability Software

We understand the product identification and traceability challenges you face throughout the lifecycle of your products. Today’s industrial coding and packaging must comply with changing regulations, keep products safe, and be traceable throughout the supply chain.

Systech, a solutions division of Markem-Imaje, delivers automated coding optimization software and end-to-end supply chain tracking to meet these demanding requirements—all while increasing productivity and minimizing human error and costs.

Our package coding and label management automation helps you accurately handle complex messages and streamline production. Reduce the costs of manual entry and message data maintenance by up to 90% and cut changeover duration by up to 50%.

Automated message design, fewer mistakes

- Design and manage complex messages from one central, intuitive interface Accelerate line startup and changeover time, SKU data entry, and message data maintenance

- Accelerate line startup and changeover time, SKU data entry, and message data maintenance

- Minimize risk of operator error and time spent manually copying data across production lines

Systech’s automated inspection solutions combine robust machine vision with intuitive interfaces to provide a one-stop-shop for integrated printing and verification. Our seamless platform confirms that your packaging and industrial coding are consistently compliant and of the highest quality.

Advanced vision inspection, dependable verification

- Verify package labeling, contents, and data for a broad variety of container types

- Scan and check 100% of codes and prints to detect and correct errors in real-time

- Minimize waste and prevent lost hours of production printing incorrect codes

Effective line control improves quality, reduces costs, and helps you continually increase production output. Systech automates coding and printing processes to minimize errors and optimize effectiveness from start-up through every phase of production.

Greater uptime, maximum OEE

- Select one correct job each time to avoid costly changeovers and minimize operator mistakes

- Instantly access performance indicators from printing and line equipment; get immediate alerts when problems occur

- Leverage real-time and historical data to identify bottlenecks, optimize printer performance and implement process improvements

As the industry leader and pioneer in serialization software, Systech delivers full-stack capabilities that can be deployed rapidly on any line, site, or enterprise in any region. Our serialization and track-and-trace software is configurable for unbeatable ease of implementation and speed to accommodate changing demands and meet regulatory compliance.

Proven, full-stack platform

- Create unique product identifiers, automate pallet labeling, and aggregate every packaging level for seamless traceability

- Provide site-level master data, serial number management, event reporting, and offline serialization packing operations

- Establish enterprise-level connectivity with comprehensive track-and-trace and compliance integrations

Mixing and matching traceability tools from different vendors can be overwhelming and costly. Systech provides a single, simple solution for generating, managing, and reporting product data in a diverse supply chain ecosystem. Our track-and-trace solution makes it easy to create a compliant system of record for your products in changing regulatory environments.

Secure, end-to-end supply chain tracking

- Get item transfer visibility and secure data exchange across your global supply chain

- Create, modify and order the processing of data based on your requirements

- Establish multiple levels of user restrictions and redundancy for everyone in your supply chain ecosystem

Product authentication at the individual item level is the most effective way to prevent counterfeiting and diversion. Systech’s revolutionary e-Fingerprint® technology turns your existing package barcode into a unique digital identifier. Each product becomes instantly connected to verify authenticity, gather actionable supply chain insight, and engage consumers.

Non-additive, digital connectivity

- Connect physical products to the digital supply chain for item-level authentication and traceability

- Detect product counterfeiting and diversion issues in real-time

- Deliver item-specific details and capture consumer feedback using a simple smartphone app